OD GEAR INSPECTION

Quality Lab Approved, Shop Floor Abused

OD GEAR INSPECTION

Quality Lab Approved, Shop Floor Abused

MODEL 8600

Setting the standard for flexible external gear inspection.

Measures OD 0mm – 225mm

Features:

- +/- .001MM repeatability

- Sealed Digital Readout System with inch/metric capabilities

- Cushioned Gauge head for consistent gauging between operators

- Roller bearing platen locator

- Robust design for years of use

- All O.D. ball, pin, or specialty anvils are interchangeable

- All 8600 series platen locators are interchangeable

- Setting master not required, but can be provided

Options:

- Output port for data collection

- Wireless data collection

- Turret style gauging (DOB/DOP, Minor, Major)

- Vertical center attachment to locate shafts

- Stand on roller bearing wheels with storage drawer

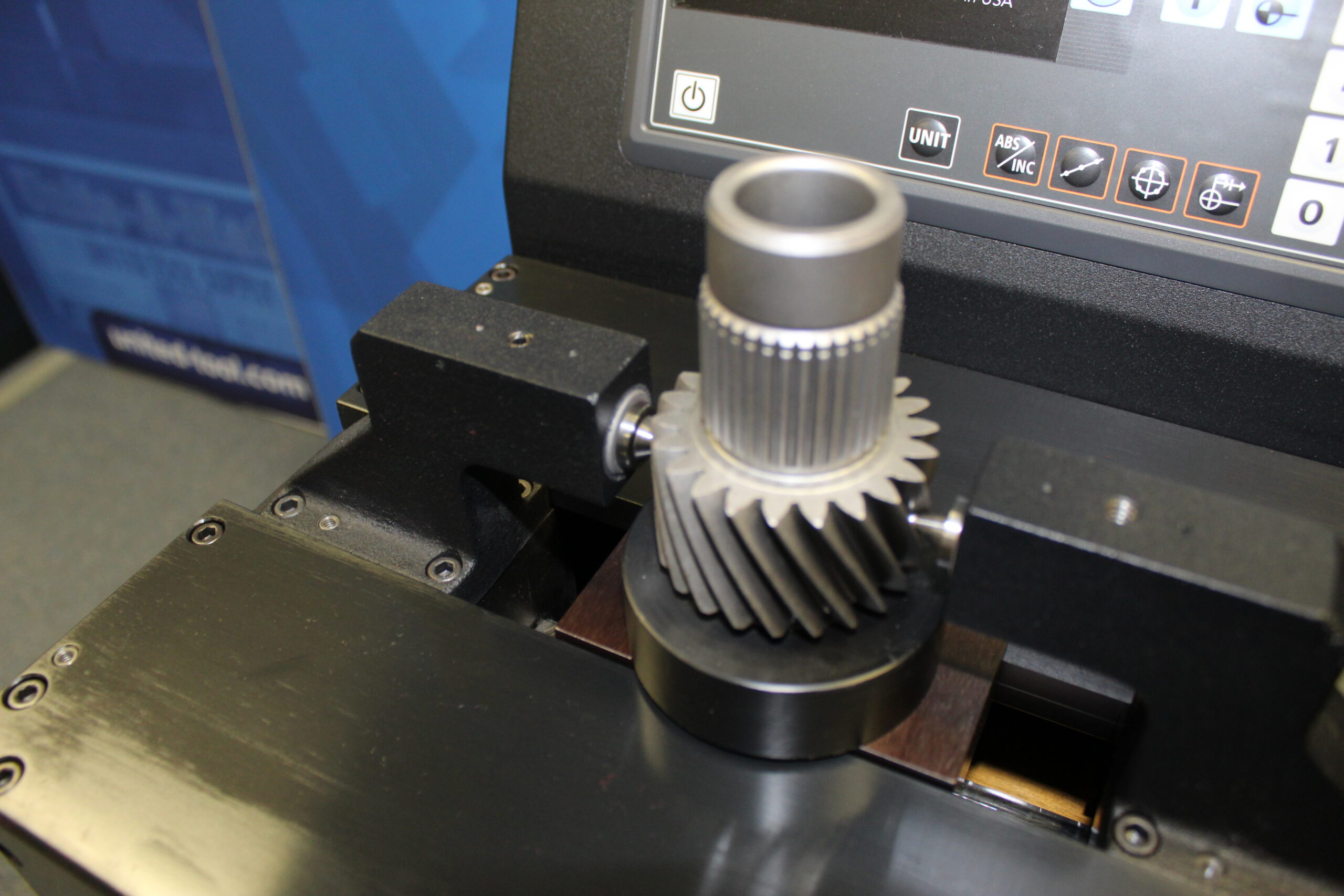

MODEL 2000

The evolution of bench-top pinion and sun gear inspection.

Measures OD 0mm – 75mm

Features:

- +/- .001MM repeatability

- Sealed Digital Readout System with inch/metric capabilities

- Cushioned Gauge head for consistent gauging between operators

- Roller bearing platen locator

- Robust design for years of use

- All O.D. ball, pin, or specialty anvils are interchangeable

- All 2000 series platen locators are interchangeable

- Setting master not required, but can be provided

Options:

- Output port for data collection

- Wireless data collection

- Turret style gauging (DOB/DOP, Minor, Major)

- Stand on roller bearing wheels with storage drawer

Outside Diameter (OD) inspection machines from United Tool Supply offer a highly accurate way to measure the external dimensions of gears (Spur, Helical) and splines. Our OD gauges use precision cushioned actuation to determine variances in part diameters quickly and with repeatability of 0.00005 inches (0.001mm). During inspection, the isolation of the operator from the gaging process allows for extremely high repeatability. Our products ease of use enables operators to be trained quickly.

OD inspection provides fast, reliable and robust gauging which can be used in the shop floor environment or in the quality lab. United Tool Supply configures OD inspection machines with digital readouts, data output, and statistical process control capabilities as required by its customers and our unique design allows for easy part changeover. With superior gaging technology and robust construction, our OD inspection machines deliver the precision dimensional measurement today’s manufacturers demand.

MODEL 2000

The evolution of bench-top pinion and sun gear inspection.

Measures OD 0mm – 75mm

Features:

- +/- .001MM repeatability

- Sealed Digital Readout System with inch/metric capabilities

- Cushioned Gauge head for consistent gauging between operators

- Roller bearing platen locator

- Robust design for years of use

- All O.D. ball, pin, or specialty anvils are interchangeable

- All 2000 series platen locators are interchangeable

- Setting master not required, but can be provided

Options:

- Output port for data collection

- Wireless data collection

- Turret style gauging (DOB/DOP, Minor, Major)

- Stand on roller bearing wheels with storage drawer