PD Inspection Gauges

Quality Lab Approved, Shop Floor Abused

PD Inspection Gauges

Quality Lab Approved, Shop Floor Abused

Our PD Inspection Gauges for Precise Gear Measurement: ID & OD Inspection

In gear manufacturing, precision is everything. PD (Pitch Diameter) inspection gauges are essential tools used to measure the critical dimensions of gears, ensuring their performance and reliability. These gauges play a crucial role in both internal diameter (ID) and external diameter (OD) gear inspections, helping manufacturers meet exacting standards in industries ranging from automotive to heavy machinery.

What Are PD Inspection Gauges?

PD inspection gauges are precision instruments used to measure the pitch diameter of gears. This key dimension influences how gears mesh and transfer power, making accurate measurement vital to avoiding gear failure, misalignment, or excessive wear. PD gauges are designed to inspect gears with both internal and external diameters, making them versatile for various gear profiles and types, including spur, helical, and bevel gears.

Key Applications: ID & OD Gear Inspection

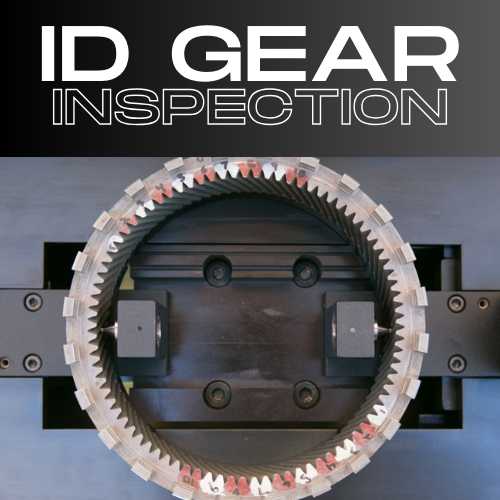

- ID (Internal Diameter) Gear Inspection: PD inspection gauges are ideal for measuring the internal pitch diameter of gears. This is critical for ensuring proper fit and alignment with external gears or shafts. By using a PD gauge, manufacturers can ensure that the ID of gears is within tolerance, preventing issues like excessive backlash or uneven load distribution.

- OD (External Diameter) Gear Inspection: For gears with an external diameter, PD inspection gauges help verify the gear’s pitch diameter to guarantee smooth meshing with internal gears or other components. Accurate OD gear inspection ensures the gears maintain proper engagement and function, reducing wear and extending the lifespan of machinery.

Benefits of Using PD Inspection Gauges

- Unmatched Precision: PD gauges are designed for precise, repeatable measurements, ensuring that gear pitch diameters meet exact specifications.

- Versatile Applications: Whether you’re inspecting internal or external diameters, these gauges are suitable for a wide variety of gear types and sizes.

- Increased Efficiency: PD inspection gauges help speed up the inspection process, allowing for quick assessments while maintaining high accuracy.

- Quality Control: Regular gear inspection using PD gauges minimizes the risk of defects, ensuring that your gears will function smoothly in high-performance applications.

Why Accurate ID & OD Gear Inspection Matters

Accurate measurement of both internal and external pitch diameters is essential to gear performance. Proper ID and OD gear inspection helps:

- Prevent Gear Misalignment: Ensuring that gears mesh properly, reducing the risk of costly equipment failure.

- Optimize Load Distribution: Maintaining correct pitch diameter helps distribute loads evenly, extending the operational life of gears and related components.

- Enhance Gear Efficiency: Well-measured gears operate more smoothly, minimizing friction and energy loss in mechanical systems.

Find the Right PD Inspection Gauges for Your Needs

At United Tool Supply, we offer a range of PD inspection gauges specifically designed for accurate ID and OD gear inspections. Our tools are built to help you meet strict quality standards while ensuring efficiency in your production processes. Contact us today to learn more about how our PD gauges can support your gear manufacturing operations.

Our PD Inspection Gauges for Precise Gear Measurement: ID & OD Inspection

In gear manufacturing, precision is everything. PD (Pitch Diameter) inspection gauges are essential tools used to measure the critical dimensions of gears, ensuring their performance and reliability. These gauges play a crucial role in both internal diameter (ID) and external diameter (OD) gear inspections, helping manufacturers meet exacting standards in industries ranging from automotive to heavy machinery.

What Are PD Inspection Gauges?

PD inspection gauges are precision instruments used to measure the pitch diameter of gears. This key dimension influences how gears mesh and transfer power, making accurate measurement vital to avoiding gear failure, misalignment, or excessive wear. PD gauges are designed to inspect gears with both internal and external diameters, making them versatile for various gear profiles and types, including spur, helical, and bevel gears.

Key Applications: ID & OD Gear Inspection

- ID (Internal Diameter) Gear Inspection: PD inspection gauges are ideal for measuring the internal pitch diameter of gears. This is critical for ensuring proper fit and alignment with external gears or shafts. By using a PD gauge, manufacturers can ensure that the ID of gears is within tolerance, preventing issues like excessive backlash or uneven load distribution.

- OD (External Diameter) Gear Inspection: For gears with an external diameter, PD inspection gauges help verify the gear’s pitch diameter to guarantee smooth meshing with internal gears or other components. Accurate OD gear inspection ensures the gears maintain proper engagement and function, reducing wear and extending the lifespan of machinery.

Benefits of Using PD Inspection Gauges

- Unmatched Precision: PD gauges are designed for precise, repeatable measurements, ensuring that gear pitch diameters meet exact specifications.

- Versatile Applications: Whether you’re inspecting internal or external diameters, these gauges are suitable for a wide variety of gear types and sizes.

- Increased Efficiency: PD inspection gauges help speed up the inspection process, allowing for quick assessments while maintaining high accuracy.

- Quality Control: Regular gear inspection using PD gauges minimizes the risk of defects, ensuring that your gears will function smoothly in high-performance applications.

Why Accurate ID & OD Gear Inspection Matters

Accurate measurement of both internal and external pitch diameters is essential to gear performance. Proper ID and OD gear inspection helps:

- Prevent Gear Misalignment: Ensuring that gears mesh properly, reducing the risk of costly equipment failure.

- Optimize Load Distribution: Maintaining correct pitch diameter helps distribute loads evenly, extending the operational life of gears and related components.

- Enhance Gear Efficiency: Well-measured gears operate more smoothly, minimizing friction and energy loss in mechanical systems.

Find the Right PD Inspection Gauges for Your Needs

At United Tool Supply, we offer a range of PD inspection gauges specifically designed for accurate ID and OD gear inspections. Our tools are built to help you meet strict quality standards while ensuring efficiency in your production processes. Contact us today to learn more about how our PD gauges can support your gear manufacturing operations.