ID GEAR INSPECTION

Quality Lab Approved, Shop Floor Abused

ID GEAR INSPECTION

Quality Lab Approved, Shop Floor Abused

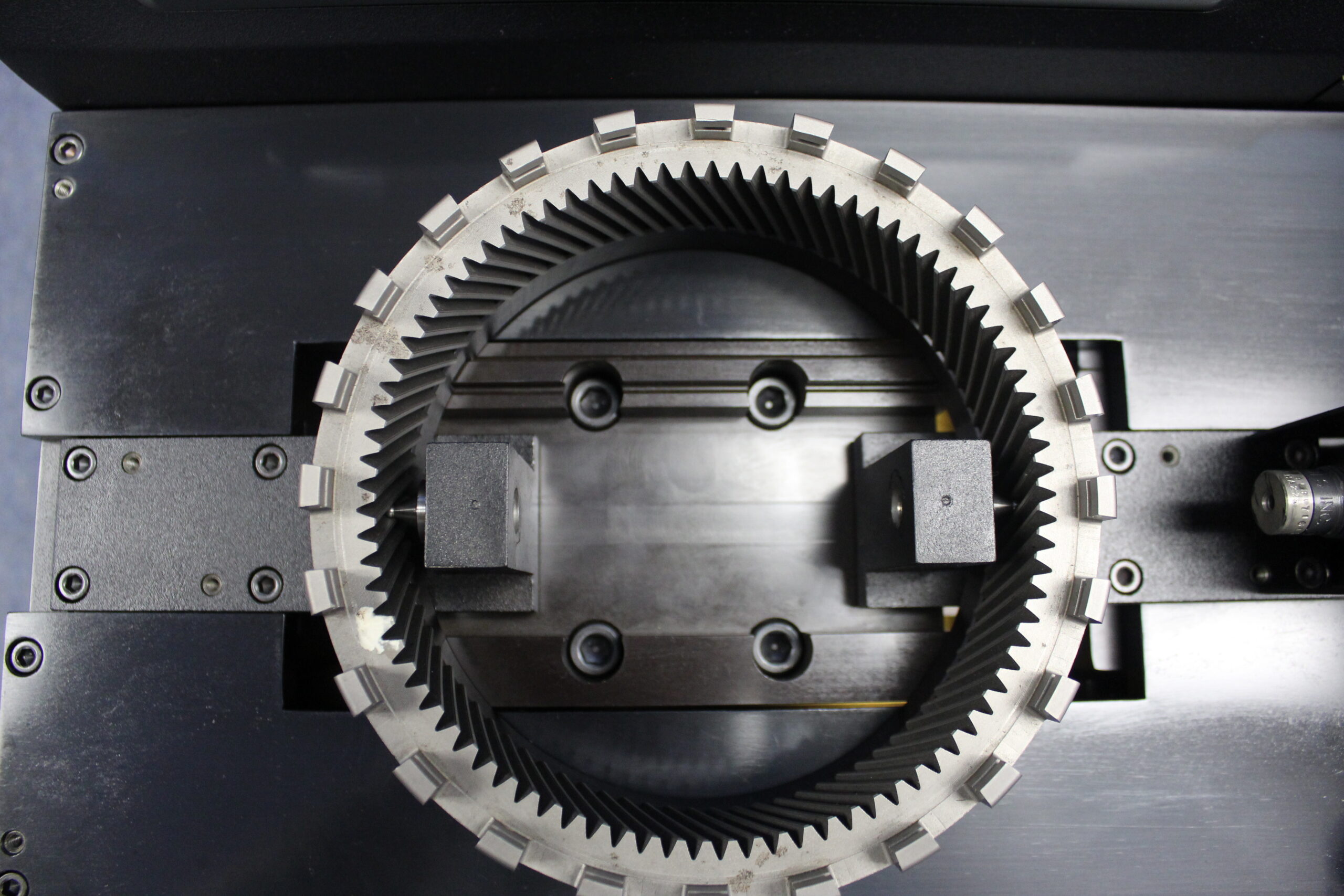

MODEL 8620

Setting the standard for flexible internal gear/spline inspection.

measures up to 225mm

Features:

- +/- .001MM repeatability

- Sealed Digital Readout System with inch/metric capabilities

- Cushioned Gauge head for consistent gauging between operators

- Roller bearing platen locator

- Robust design for years of use

- 8620 ball, pin, or specialty anvils are interchangeable.

- 8620 series platen locators are interchangeable

- 8620 requires setting master

Options:

- Output port for data collection

- Wireless data collection

- Stand on roller bearing wheels with storage drawer

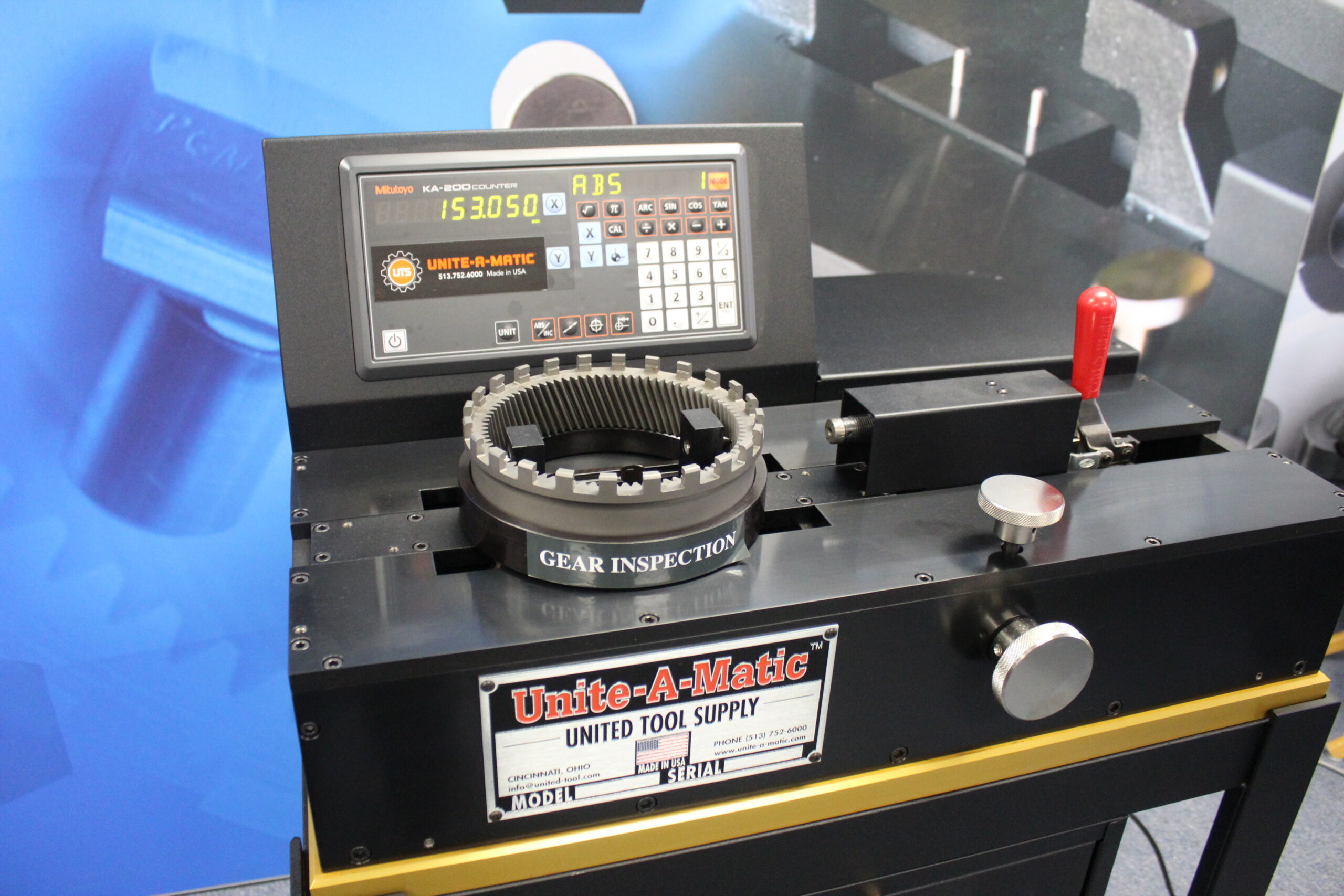

MODEL 2020

Accurate, stable, bench-top solution for small internal spline inspection.

measures up to 75mm

Features:

- +/- .001MM repeatability

- Sealed Digital Readout System with inch/metric capabilities

- Cushioned Gauge head for consistent gauging between operators

- Roller bearing platen locator

- Robust design for years of use

- 2020 ball, pin, or specialty anvils are interchangeable

- 2020 series platen locators are interchangeable

- 2020 requires setting master

Options:

- Output port for data collection

- Wireless data collection

- Stand on roller bearing wheels with storage drawer

MODEL 2020

Accurate, stable, bench-top solution for small internal spline inspection.

measures up to 75mm

Features:

- +/- .001MM repeatability

- Sealed Digital Readout System with inch/metric capabilities

- Cushioned Gauge head for consistent gauging between operators

- Roller bearing platen locator

- Robust design for years of use

- 2020 ball, pin, or specialty anvils are interchangeable

- 2020 series platen locators are interchangeable

- 2020 requires setting master

Options:

- Output port for data collection

- Wireless data collection

- Stand on roller bearing wheels with storage drawer

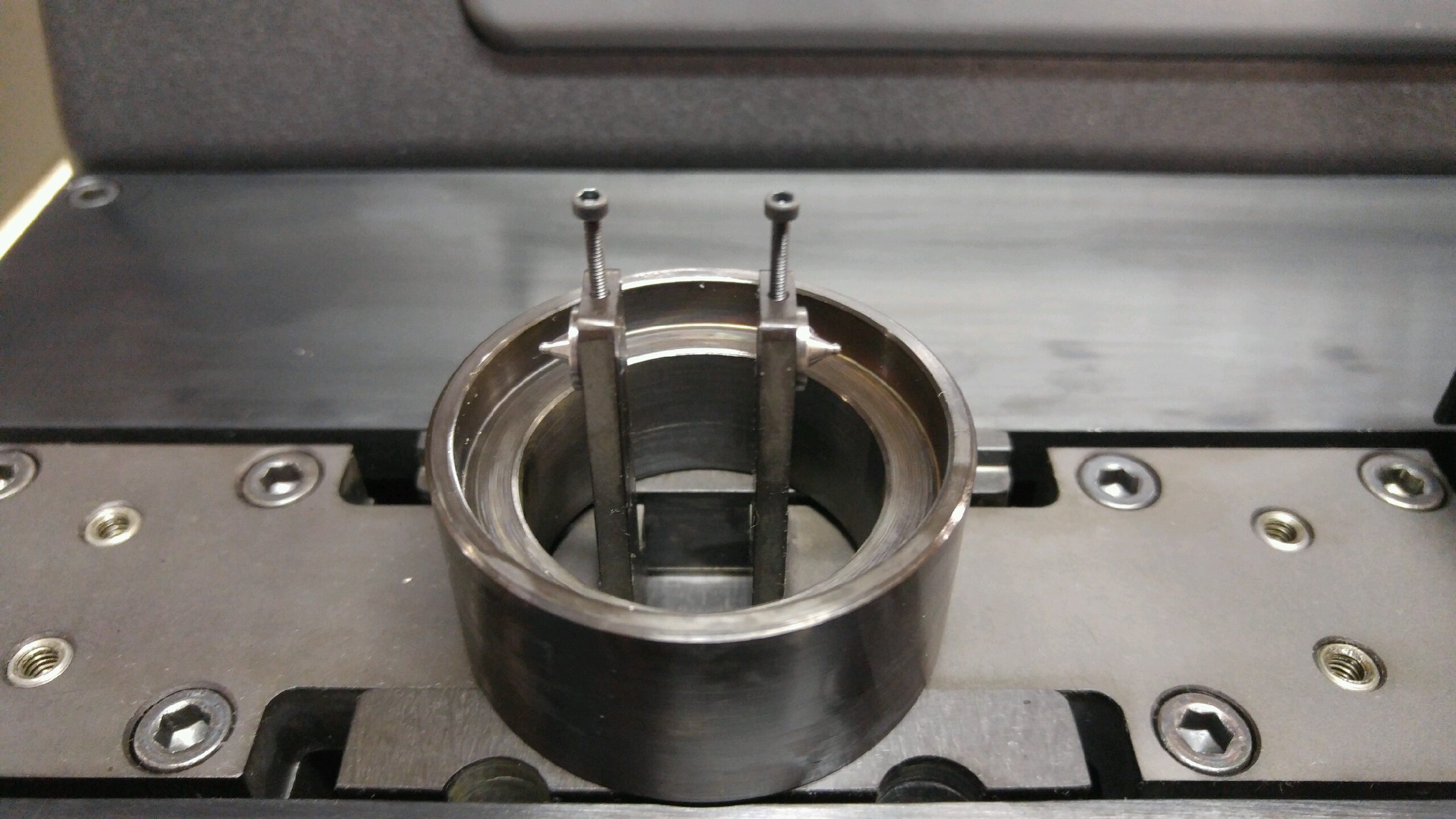

Inside Diameter (ID) inspection machines from United Tool Supply provide accurate measurement of internal diameters for gears and splines. Our ID gauge heads utilize precision cushioned gaging to deliver repeatable results between operators within 0.00005 inches (0.001mm). Our Internal units are flexible with interchangeable locators and tooling to gauge diameters at multiple locations along the length or depth of parts. Our universal design can accommodate families of internal parts with quick changeover. During inspection, the ID gauge expands against the inner walls of the hole or cavity being measured. This allows any deviations from the nominal diameter to be instantly detected. Pass/fail analyses are performed quickly based on comparison to specifications.

United Tool Supply outfits our ID inspection machines with digital readouts and data output for SPC controls. Customized configurations with automated features are available for quality control and process improvements. With superior technology and robust designs, our ID inspection machines provide manufacturers the utmost accuracy in internal dimensional verification. Contact United Tool Supply today to bring repeatable, reliable ID measurement to your production line.