Welcome to United Tool Supply, a family-owned business providing high-quality inspection tools and equipment since 1973. Located just outside Cincinnati, Ohio, United Tool Supply manufactures precision ID and OD gear/spline gauges and surface finish/runout inspection machines under our Unite-A-Matic and Roll-A-Matic product lines. As an authorized Mitutoyo distributor for over 50 years, we also stock a full range of Mitutoyo metrology products.

In 2021, UTS purchased Karr Metrology Instruments which rounded out the entire measurement tool product offering. With decades of experience and expertise, our knowledgeable staff can help recommend the right inspection and measuring tools to improve quality control and boost productivity for manufacturers across industries. We pride ourselves on delivering customized solutions, exceptional customer service and top-tier products to clients across the globe. Contact us today to learn how we can help take your manufacturing inspection and quality assurance to the next level.

Celebrating 50+ Years

Welcome to United Tool Supply

United Tool Supply, a family-owned business providing high-quality inspection tools and equipment since 1973. Located just outside Cincinnati, Ohio.

(click for more)

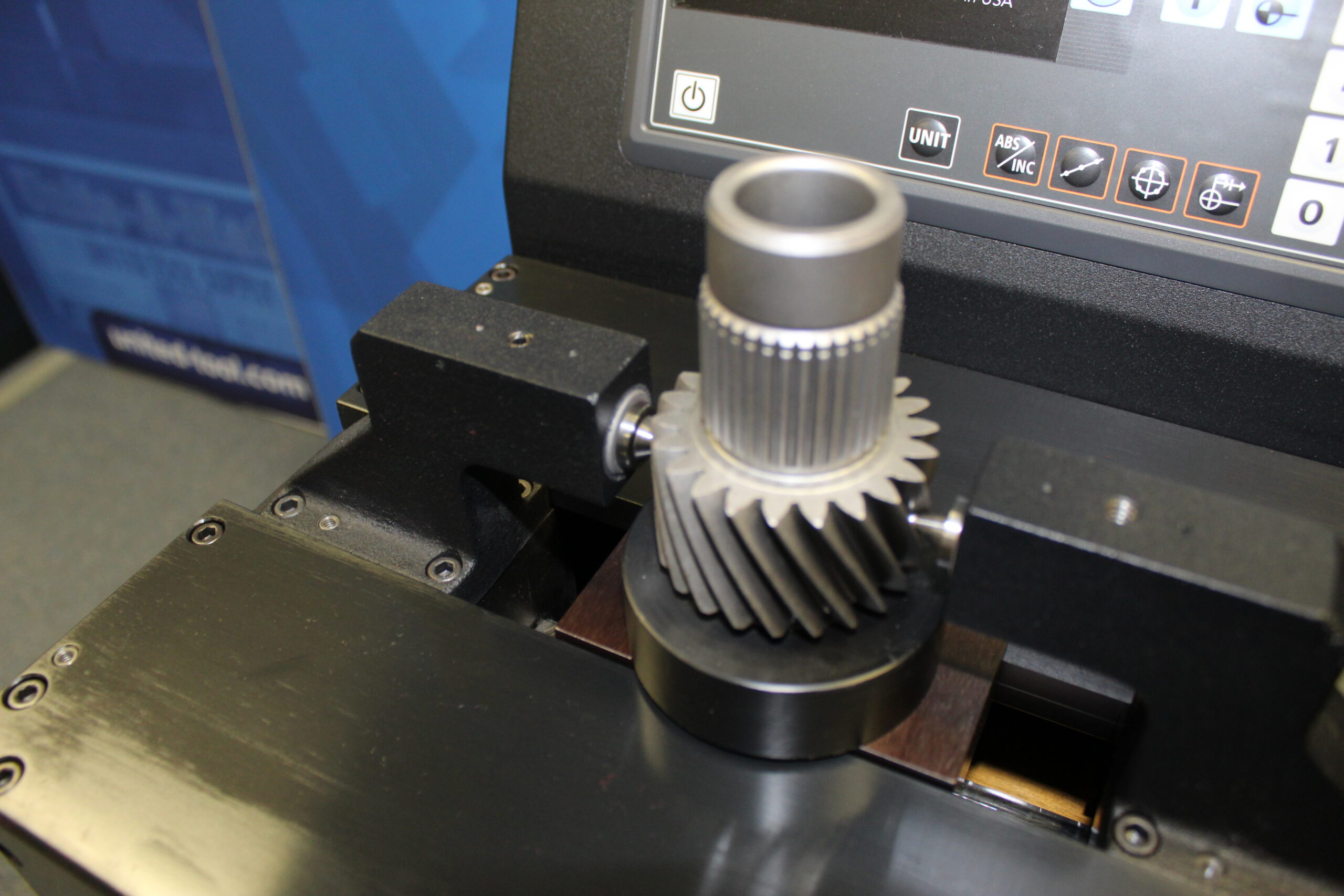

United Tool Supply manufactures precision ID and OD gear/spline gauges and surface finish/runout inspection machines under our Unite-A-Matic and Roll-A-Matic product lines. As an authorized Mitutoyo distributor for over 50 years, we also stock a full range of Mitutoyo metrology products.

UTS purchased Karr Metrology Instruments

In 2021, UTS purchased Karr Metrology Instruments which rounded out the entire measurement tool product offering.

(click for more)

With decades of experience and expertise, our knowledgeable staff can help recommend the right inspection and measuring tools to improve quality control and boost productivity for manufacturers across industries. We pride ourselves on delivering customized solutions, exceptional customer service and top-tier products to clients across the globe. Contact us today to learn how we can help take your manufacturing inspection and quality assurance to the next level.

TRUE DIMENSION

GEAR INSPECTION©

“Even when companies can go to one of our competitors, they come to us because they know what they’re going to get.

That makes us always focus on quality, which means everything we send out has to be perfect. I personally check every machine that goes out.

(click for more)

It’s not like this is something we only do to make a living. This is something we do because we actually enjoy it, and we take a lot of pride in it.”

– Jeff Young, Gear Solutions Magazine

TRUE DIMENSION

GEAR INSPECTION™

“Even when companies can go to one of our competitors, they come to us because they know what they’re going to get.

That makes us always focus on quality, which means everything we send out has to be perfect. I personally check every machine that goes out.

It’s not like this is something we only do to make a living. This is something we do because we actually enjoy it, and we take a lot of pride in it.”

– Jeff Young, Gear Solutions Magazine